Rollers for paper and cardboard

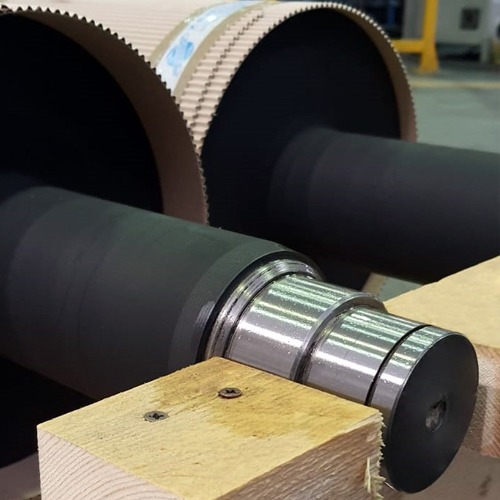

Rubber coating rollers

Rubber coating rollers have different functions in paper and cardboard processing machines including towing, transport, pressure on the treated material and more.

The surface, which is the area of contact with the treated product, can be coated with different materials including: silicone, hypalon, polyurethane, neoprene, EPDM, viton and other elastomers according to drawing.

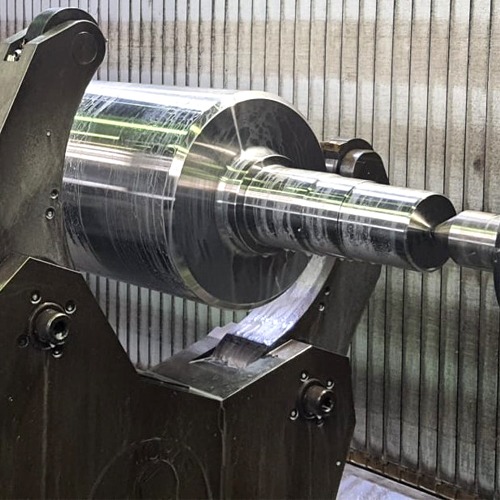

Plate holder rollers

The plate holder rollers have the function of supporting the plate, which in turn has the purpose of bringing the image back to the treated product. The plate holder rollers usually have two characteristics: a milling along the entire length of the table necessary for blocking the plate and an axial and circular groove on the entire roller necessary as a reference for positioning the plate.

The surface, which is the area of contact with the product, can be maintained by a grinding finishing or coated. The possible coatings are: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick coatings and more on request.

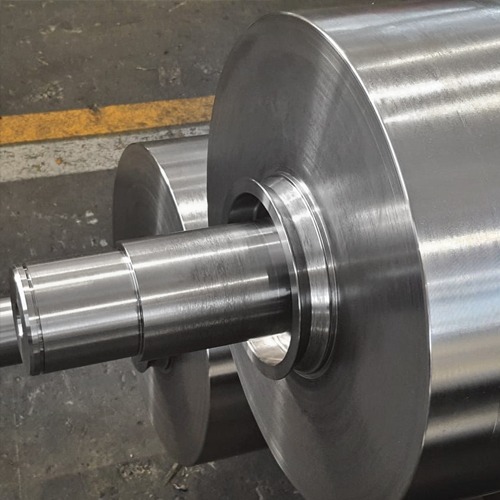

Die-holder rollers

The die-holder rollers have the function of supporting the die which in turn has the purpose of cutting and shaping the product. The die-holder rollers have the characteristic of having, on the surface numerous holes with tapping that allow the correct fixing of the cutting and modeling apparatus.

The surface, which is the area of contact with the product, can be maintained by a grinding finishing or coated. The possible coatings are: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick coatings and more on request.

Rubber coating rollers

Plate holder rollers

Die-holder rollers

Rollers against die

Creasing rollers

Creasing rollers

Transport rollers

Rollers against die

The rollers against the die have the function of keeping the product in contact with the die-holder roller during the die-cutting phase. This type of roller must have a high surface resistance for this, usually, the surface, which is the area of contact with the product, can be maintained by a grinding finishing or coated.

The possible coatings are: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick coatings and more on request.

Creasing rollers

The creasing rollers have the function of supporting the creasing organ which, in turn, has the purpose of making folds on the product. Creasing rolls, like plate-holder rollers, usually have two characteristics: a milling along the entire length of the surface necessary for blocking the plate and an axial and circular groove on the entire roller necessary as a reference for positioning the plate.

The surface, which is the area of contact with the product, can be maintained by a grinding finishing or coated. The possible coatings are: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick coatings and more on request.

Guide rollers

The guide rollers have the function of guiding the product during its transit inside the plant. This prevents the layer of paper or cardboard from going out of the correct trajectory and therefore leading to a subsequent stop of the plant.

The surface, which is the area of contact with the product, can be finished cylindrical, conical, concave or convex with turning or grinding. Subsequently, different coatings can be made such as: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick coatings, silicone, hypalon, polyurethane, neoprene, EPDM, viton, zinc plating, painting and more on request.