Rollers for printing machines

Standard anilox inking rolls

The anilox inking rollers have the function of withdrawing the ink from the containment tray and then depositing it, with the right dosage, on the printing roller.

This phase is made possible thanks to the particular surface finishing, characterized by an engraving of different shape that allows to create pits dedicated to containing the ink.

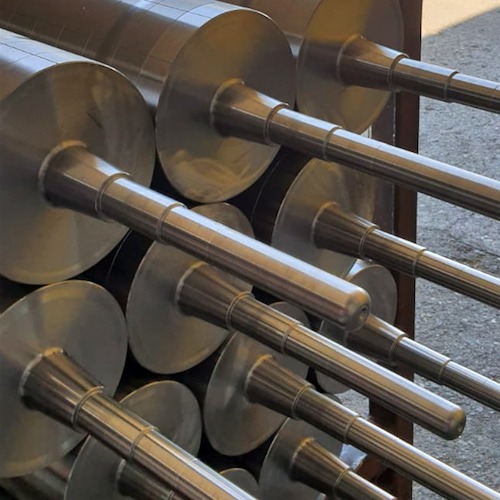

Standard anilox rolls can be structured in two ways:

- Roller with direct engraving on the surface;

- Support spindle and interchangeable sleeve with engraving.

The difference between the two types of structure is that, by using the roller engraved directly on the surface, it is not possible to easily change the type of engraving except by carrying out a surface remaking. The structure consisting of spindle and sleeve gives the possibility of having more sleeves with different engravings and therefore greater working flexibility, (?) Increasing the ease of format change, cost reduction and simplified handling given by the reduced weight of the sleeve.

To allow the locking and unlocking of the sleeve, a compressed air connection is required.

The surface can be directly engraved on the steel or be coated and successively engraved.

The coatings can be in copper or ceramic material and can be carried out both on the sleeve and directly on the roller surface.

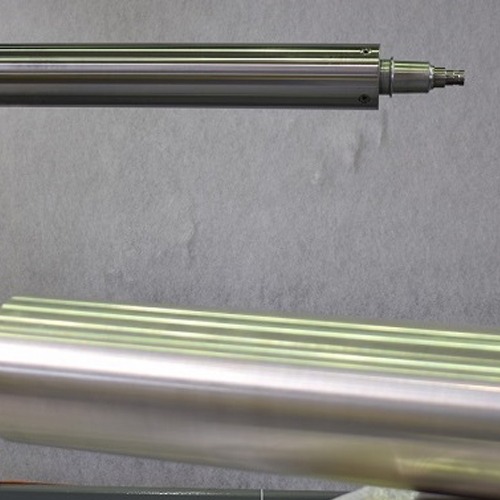

Anilox inking rollers with sleeve totally in aluminum patented by Zenit S.p.A.

The type of anilox inking roller patented by us has the peculiarity of mounting a sleeve entirely in aluminum and not in multi-material like the standard ones.

The benefits achievable thanks to the anilox rolls with entirely aluminum sleeves are:

- Reduce the costs of purchasing and replacing sleeves;

- Increase the accuracy, given the stiffness of a sleeve composed solely of a material such as aluminum;

- Reduce the environmental impact and disposal costs, avoiding the use of composite polymeric materials;

- Facilitate the handling of the sleeve by the operator, thanks to the weight reduction compared to a standard one (about the half).

The user, deciding to use this type of roller, will not need to modify the machine; in fact, our project starts with the idea of locking and unlocking the sleeve using compressed air as in standard rollers.

The surface of the aluminum sleeve will then be coated with ceramic material and processed with any type of engraving.

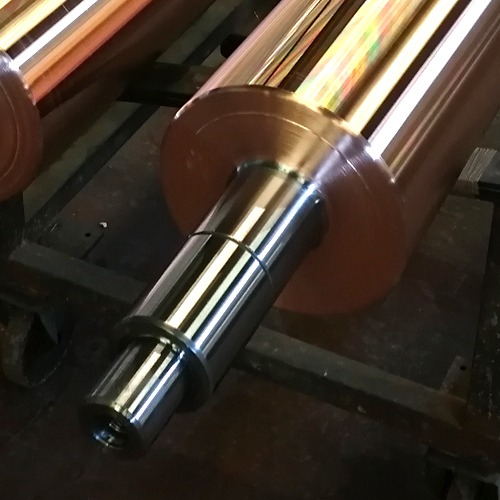

Copper-plated rollers for rotogravure printing

In rotogravure printing machines the passage of the ink takes place directly from the roller to the film to be printed.

Printing rollers for rotogravure machines are metal rollers, which have a copper coating on the surface, i.e. the area of contact with the product to be printed. The subject to be printed is engraved on the copper layer.

Standard anilox inking rolls

Anilox inking rollers with sleeve totally in aluminum patented by Zenit S.p.A.

Copper-plated rollers for rotogravure printing

Plate-holder rollers