Rollers for flexible packaging

Cooled or heated calenders

Cooled or heated calenders are rollers that have the function of altering the temperature of a product which flows or is deposited on their surface. The temperature differential is created thanks to the flow of a liquid, cold or hot, inside the rollers.

This type of roller can be identified through different constructions: simple flow, double cross flow, with free cavity, with spiral cavity, with constant pitch spiral or with variable pitch spiral and other on customer’s drawing.

The surface, which is the area of contact with the product, can be maintained by a grinding finishing or coated. The possible coatings are: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick and more on request.

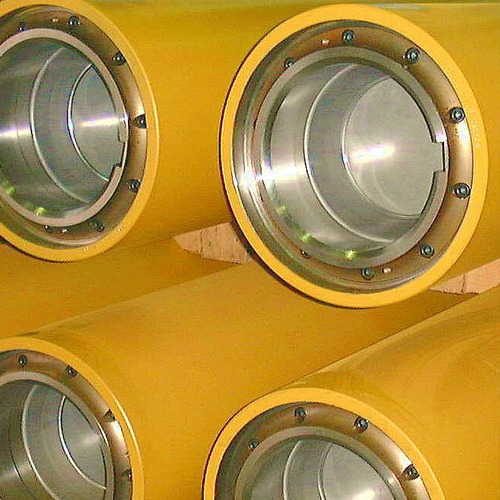

Rubber coated rollers

The rubber-coated rollers have different functions including: towing of flexible packaging, lamination of coupled flexible packaging and more.

The surface, which is the area of contact with the flexible packaging, can be coated with different materials including: silicone, hypalon, polyurethane, neoprene, EPDM, viton and other elastomers according to the drawing.

Air spindles

The air mandrels are sleeve rollers with a compressed air system for the expulsion of the sleeves. The expulsion of the sleeve is done thanks to a series of ducts which, bringing the air between the sleeve and the spindle, create an air cushion which is indispensable for the extraction of the sleeve and its change.

On the surface, that is the area of contact with the sleeve, a thickness chrome plating and subsequent grinding is usually carried out to increase the duration of the sliding surface between the spindle and the sleeve.

Cooled or heated calenders

Rubber coated rollers

Air spindles

Spindles for film winding