Rollers for sheet metal

Rubber covered rollers

Rubber covered rollers have different functions in sheet metal treatment machines including: towing, transport, pressure on the product and more. The surface, which is the area of contact with the treated product, can be coated with different materials including: silicone, hypalon, polyurethane, neoprene, EPDM, viton.

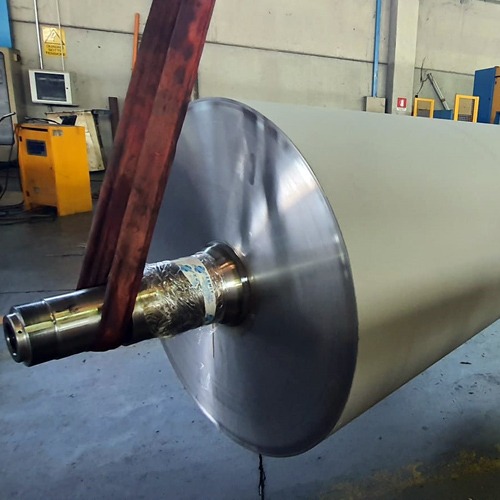

Transport rollers

The transport rollers have the function of transporting the product that is the sheet. They are usually characterized by simple journals without transmission links.

The surface, which is the area of contact with the product, can be finished cylindrical, conical, concave or convex with turning or grinding (if necessary previously treated with hardening processes), subsequently different coatings can be made such as: thick chrome plating and grinding, non-stick coatings, silicone, hypalon, polyurethane, neoprene, EPDM, viton, zinc plating, painting.

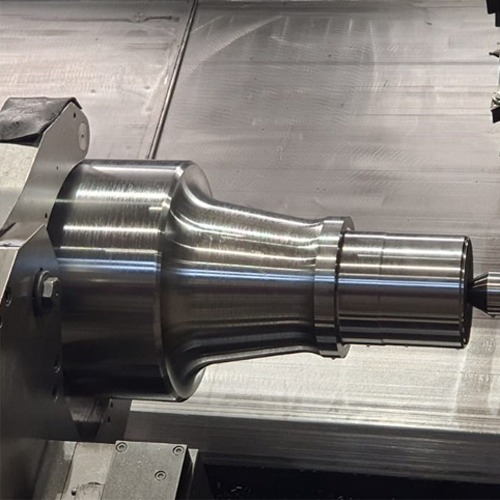

Wringer rollers

The wringer rollers have the function of eliminating the chemical agent, liquid, in excess present on the sheet.

The surface, which is the area of contact with the product, can be finished cylindrical, conical, concave or convex with turning or grinding (if necessary previously treated with hardening processes). Subsequently, different coatings can be made such as: thick chrome plating and grinding, non-stick coatings, silicone, hypalon, polyurethane, neoprene, EPDM, viton, zinc plating, painting.

Rubber covered rollers

Transport rollers

Wringer rollers

Motorized rollers

Cooling rollers

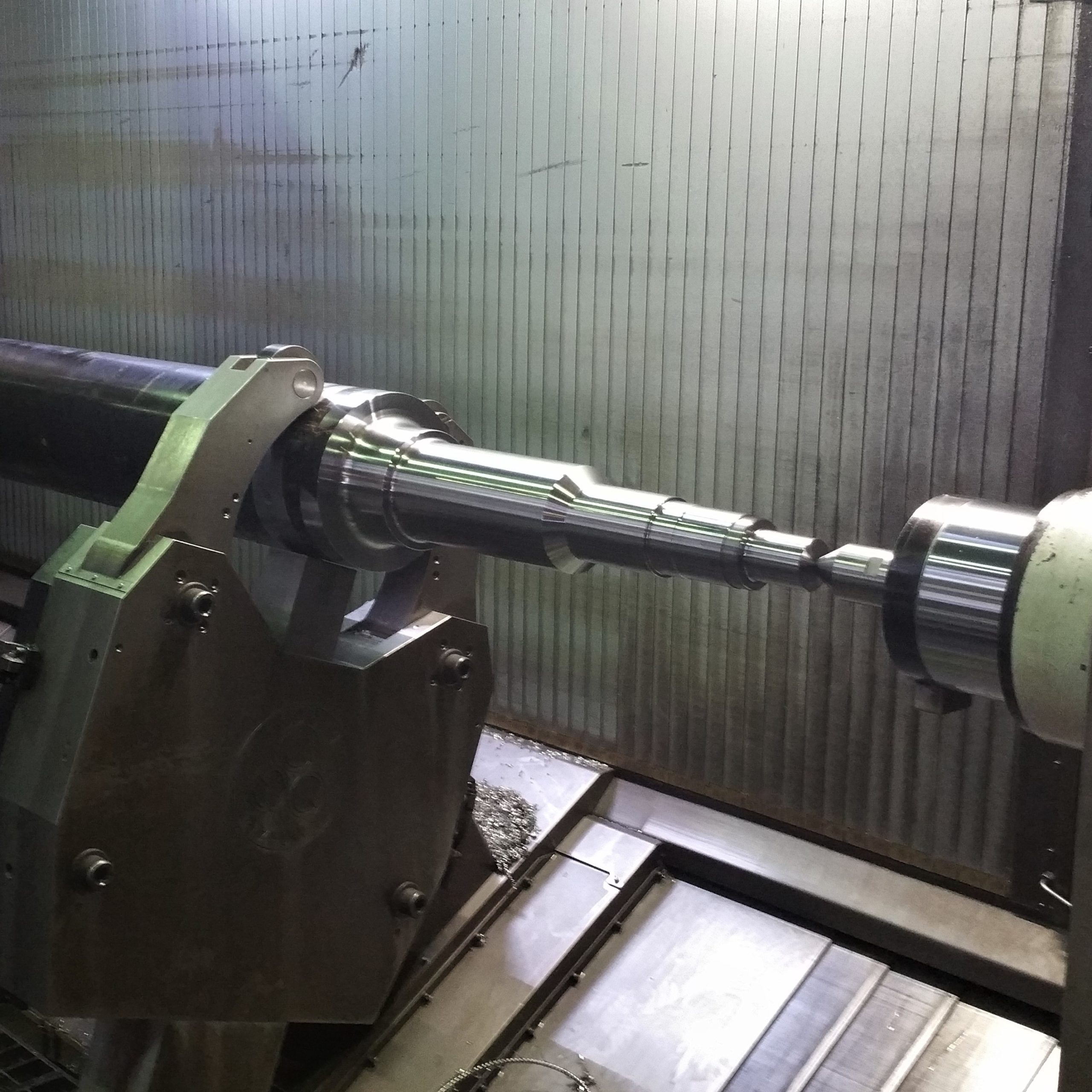

Motorized rollers

The wringer rollers have the function of eliminating the chemical agent, liquid, in excess present on the sheet.

The surface, which is the area of contact with the product, can be finished cylindrical, conical, concave or convex with turning or grinding (if necessary previously treated with hardening processes). Subsequently, different coatings can be made such as: thick chrome plating and grinding, non-stick coatings, silicone, hypalon, polyurethane, neoprene, EPDM, viton, zinc plating, painting.