Rolls for paper mills

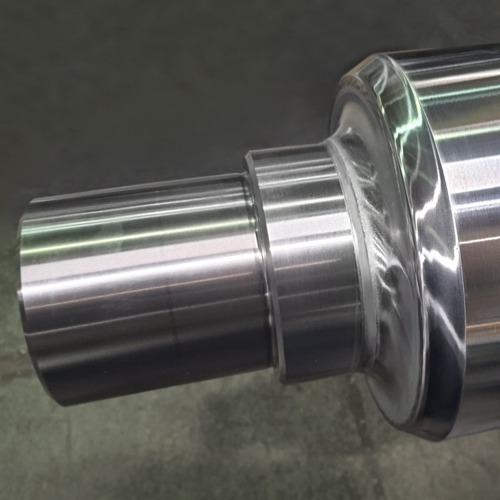

Motorized rollers

The motorized rollers have the function of transmitting the motion from the engines to the product, i.e. the paper. They are characterized, on the journals, by transmission connections of different types including seats for tabs / keys, grooved profiles, front couplings and more on request.

The surface, which is the area of contact with the product, can be finished cylindrical, conical, concave or convex with turning or grinding, subsequently different coatings can be made such as: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick coatings, silicone, hypalon, polyurethane, neoprene, EPDM, viton, zinc plating, painting and more on request.

Idle rollers

The idle rollers have the function of transporting the product that is the paper. They are usually characterized by simple journals without transmission links.

The surface, which is the area of contact with the product, can be finished cylindrical, conical, concave or convex with turning or grinding. Subsequently, different coatings can be made such as: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick coatings, silicone, hypalon, polyurethane, neoprene, EPDM, viton, zinc plating, painting and more on request.

Guide rollers

The guide rollers have the function of guiding the product during its transit inside the plant; this prevents the layer of product from leaving the correct trajectory and thus creating a subsequent plant stop.

The surface, which is the area of contact with the product, can be finished cylindrical, conical, concave or convex with turning or grinding. Subsequently, different coatings can be made such as: light polish chrome plating, light satin chrome plating, thick chrome plating and grinding, non-stick, silicone, hypalon, polyurethane, neoprene, EPDM, viton, zinc plating, painting and more on request.

Motorized rollers

Idle rollers

Guide rollers

Idler rollers