Special rollers and shafts

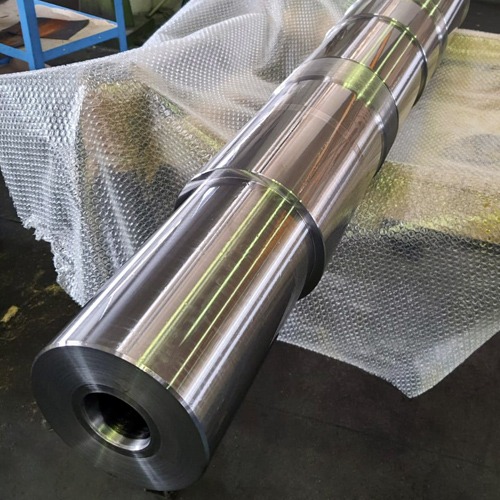

Blade holder rollers

The blade holder rollers are rollers characterized by the presence of milling, on the table, of different shapes necessary for locking the blade.

The function of this type of roller can be the clean cut of the product or the engraving.

On the surface of these rollers, in addition to the milling, dedicated to housing the blade, it will be necessary to have a locking that can be done with wedge systems, or with simple screws.

The surface, not being in contact with the product, is usually finished by lathe. On request, to protect the roller more, it is possible to coat the area with thick chrome plating and grinding, non-stick, carbide or ceramic coatings.

Shredder rollers

The shredder rollers are very similar, in terms of construction, to the blade holder rollers. The main difference is that the blade is mounted with a straighter angle. The function of these rollers is to shred the product so as to bring it to the desired sections.

The surface, not being in contact with the product, is usually finished by lathe. On request, to protect the roller more, it is possible to coat the area with thick chrome plating and grinding, non-stick, carbide or ceramic coating.

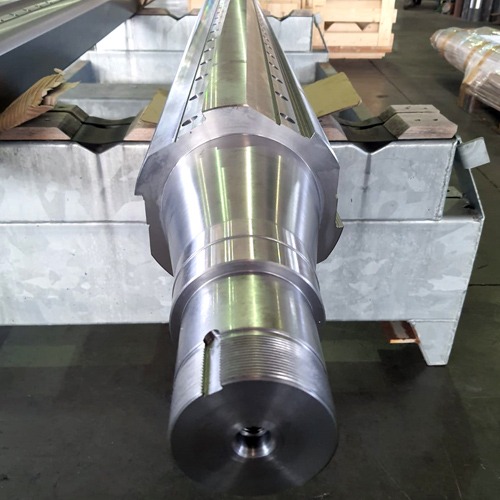

Shafts dedicated to the drilling sector

The shafts dedicated to the drilling sector have the purpose of transmitting the motion from the motorized part to the actual working and suction part.

On these shafts, we can carry out the most varied precision workings according to the customer's needs.

Blade holder rollers

Shredder rollers

Shafts dedicated to the drilling sector

Shafts for butterfly valves